Tugger Trains, Milkrun Systems, Tugger Train Systems, Tugger Carts

Tugger train systems have become an indispensable part of modern industrial production. They bundle the transports with small Tugger carts and increase the delivery frequency in order to reduce the supply quantities on assembly lines.

SCHNELLE LINKS

- Tugger train systems: economical material flow for every requirement

- Features and advantages of tugger train systems

- What is a Tugger Train?

- Types of Tugger Trains

- When are your tugger trains useful and lucrative?

- Tailor-made solution for your industrial logistics

The desire for forklift-free factories, just-in-time or just-in-sequence production is growing ever stronger. In line with this trend, tugger train systems are being used more and more frequently to provide materials in manufacturing companies.

Time-saving mass transport instead of individual transport !

With tugger train systems it is possible to deliver the material “just in time” or “just in sequence”

Tugger train systems: economical material flow for every requirement

This system enables an even utilization or a production-synchronous material supply and disposal in the given time window. Optimally coordinated processes are a decisive economic factor in industrial production and manufacturing. This also includes sophisticated logistics.

Features and advantages of tugger train systems

- Neri products have excellent directional stability, even when cornering, and deliver convincing transport performance in the tightest of spaces.

- Loading and unloading possible on one or both sides as required.

- Coupling and drawbar can be customized

- Experience has shown that the trailer modules are suitable for all conceivable loads and goods to be transported - from pallets and wire baskets to individual items.

What is a tugger train?

A tugger train is used to supply materials to the various areas of a production facility. The tugger train consists of a towing vehicle and the trailers.

As a means of transport for the internal flow of materials, the tugger train supplies various areas with materials on its tour through production or collects products at certain locations.

Since tugger trains can transport several different materials with their Tugger carts, they are highly efficient industrial trailers that both minimize and optimize internal traffic.

Thanks to their highly cyclical, often timed supply, both small batch sizes can be provided efficiently and the transport volume can be reduced by bundling individual transports.

Types of Tugger Trains

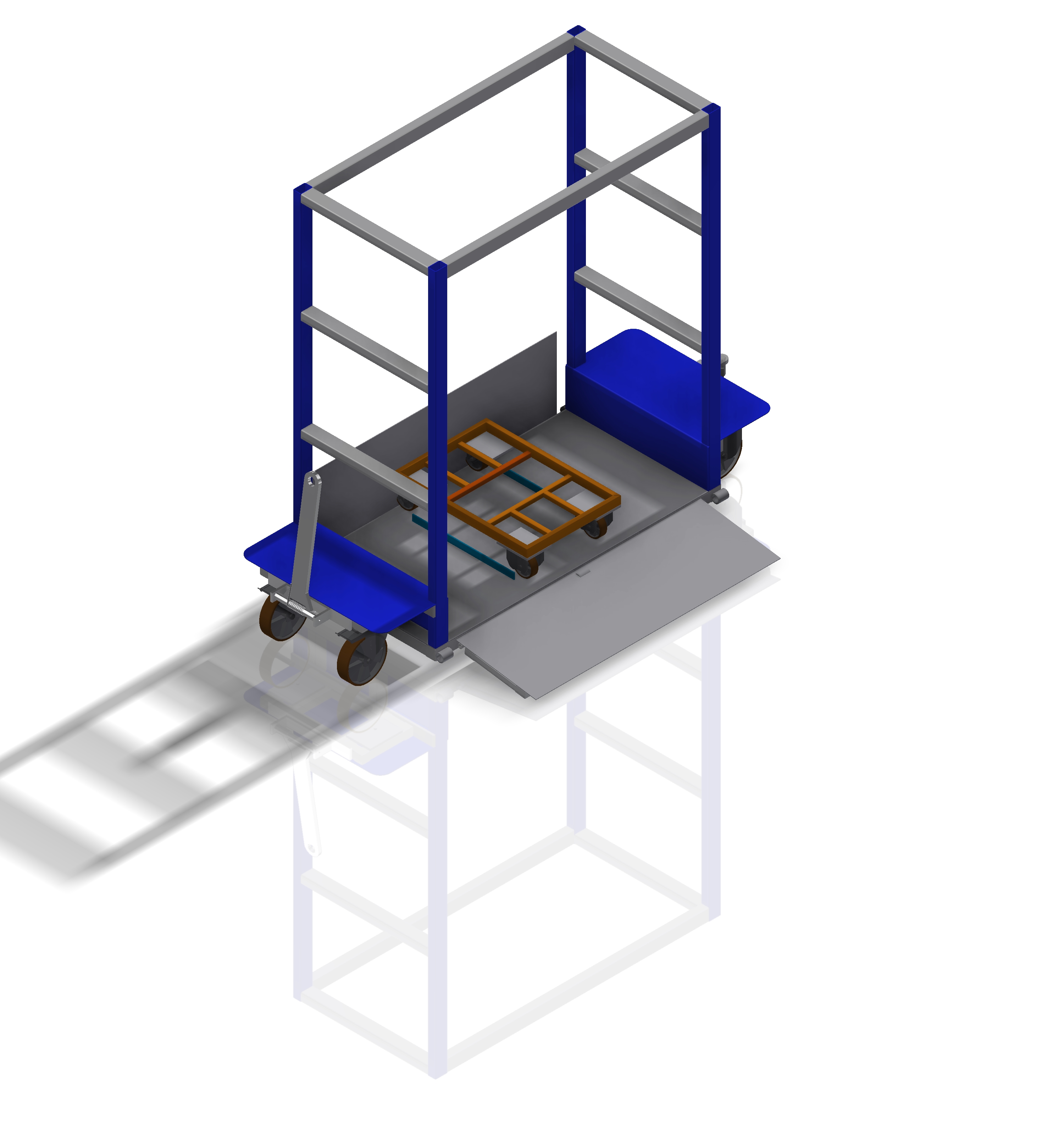

Tugger trains are available in different designs: E-, C- and H-frame, platform and taxi trolleys.

When are your tugger trains useful and lucrative? Find out with Neri!

Especially in the case of recurring transport tasks and long transport routes, tugger train systems are suitable for high-frequency delivery of a wide variety of containers in small batch sizes to different consumption points.

Tailor-made solution for your industrial logistics

This is what sets our tugger trains apart from many other conventional ones. For you, this means maximum efficiency in material flow control and less traffic in the production area.

This is what sets our tugger trains apart from many other conventional ones. For you, this means maximum efficiency in material flow control and less traffic in the production area.

Further advantages are the possibility of coupling up to six towable carts, or Tugger carts to form a train. The Tugger carts can be equipped with various hand push bars. You are as flexible as our system.